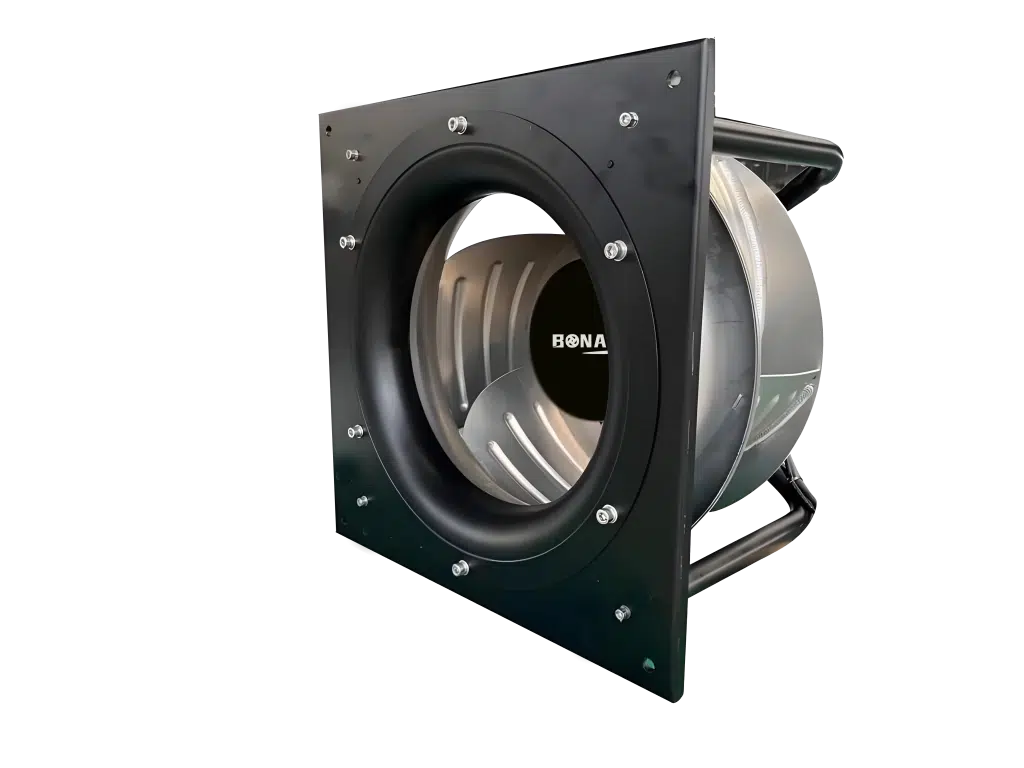

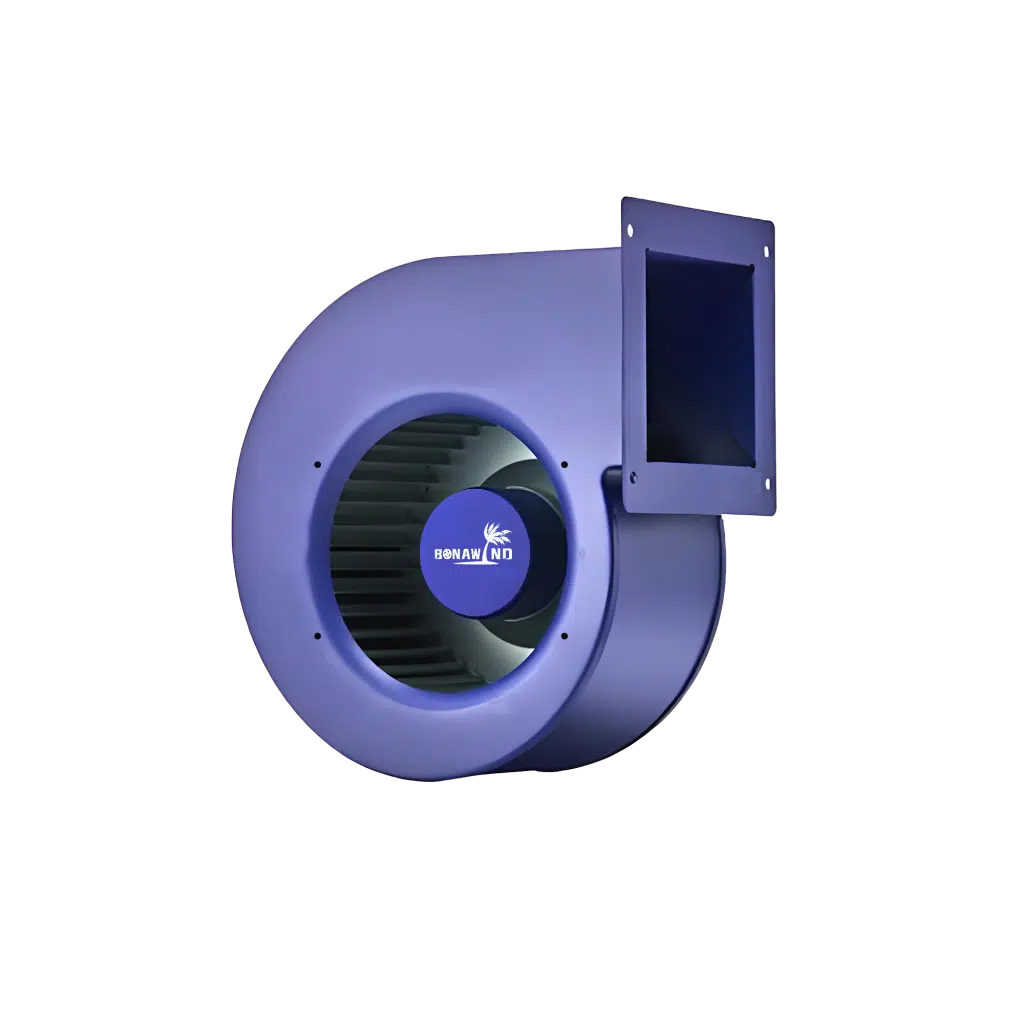

Centrifugal Fans

Reliable Centrifugal Fan Solutions Designed for Energy-Efficient Ventilation and Cooling

Product Overview

ODM

—Original Design Manufacturing

Types of Centrifugal Fans

Like other industrial and household fans, centrifugal fans come in a variety of designs to meet different needs.

Single-stage vs. Multi-stage Fans

Single-stage fans contain only one impeller and are ideal for stable, fixed airflow applications. Multi-stage fans, on the other hand, feature two or more impellers to deliver variable airflow, making them suitable for more complex operations.

Airflow Direction

Centrifugal fans can be mounted on ceilings or walls and are typically designed for either upward or downward airflow.

Upblast centrifugal fans are used to expel gases, smoke, or airborne pollutants from a specific location, such as restaurant kitchens, factories, or laboratories.

Downblast centrifugal fans draw air into a space for cooling purposes.

Key Factors to Consider When Choosing a Centrifugal Fan

Required pressure

Desired airflow volume

Ambient temperature at the installation site—higher temperatures may require higher-powered fans

Elevation of the installation location

Air quality—will the fan handle clean, polluted, dry, or humid air?

Speed Range

Centrifugal fans come with a wide range of speeds, measured in revolutions per minute (RPM). Typical fan speeds range from around 780 RPM up to 5000 RPM. Higher speeds produce stronger airflow, suitable for demanding industrial environments.

Centrifugal Fan Efficiency

The performance of different fan designs is typically evaluated by comparing the power of the air or airflow they produce to the power they consume. This ratio is known as the static efficiency or mechanical efficiency rating. Another key metric is the Pascal rating, which measures the pressure output of a specific fan.

Centrifugal fans are known for delivering consistent airflow and typically offer higher static efficiency compared to other types of fans.

Centrifugal Fans vs. Axial Fans

Centrifugal fans operate differently from commonly used axial fans.

A centrifugal fan uses a spinning impeller to draw air or gas in and push it outward through centrifugal force. During this process, the airflow changes direction both when entering and exiting the fan. Centrifugal fans pull air in at a right angle to the intake, generating higher-pressure airflow than axial fans.

In contrast:

An axial fan operates based on the principle of aerodynamic lift. Its blades are shaped like an airplane wing and draw air parallel to the central axis. As air flows over the blade surface, lift is generated, producing a high-volume, low-pressure airflow.

Key Differences:

Centrifugal Fans: Higher pressure, more efficient, better for ducted systems and harsh environments

Axial Fans: Lower power consumption, higher airflow variability, ideal for general ventilation

Contact Us

Goodwind LLC

- Address: 14615 Blue Ash Dr. Houston, TX 77090

- Telephone: 877 814 6639

- WhatsApp: 713 257 4877

- Email: info@bonawind.com