WHY COOLING MATTERS

Dairy cows are highly sensitive to heat, with their ideal environmental temperature ranging between 4 and 16 degrees Celsius. Both temperature and humidity levels play a significant role in determining the extent of heat stress a dairy cow experiences.

High temperatures can lead to:

- Milk fat depression

- Reduced fertility

- Increased health issues like dehydration, heat stroke, lowered immune system…

- General discomfort and stress, leading to lower overall performance

- Transition disease

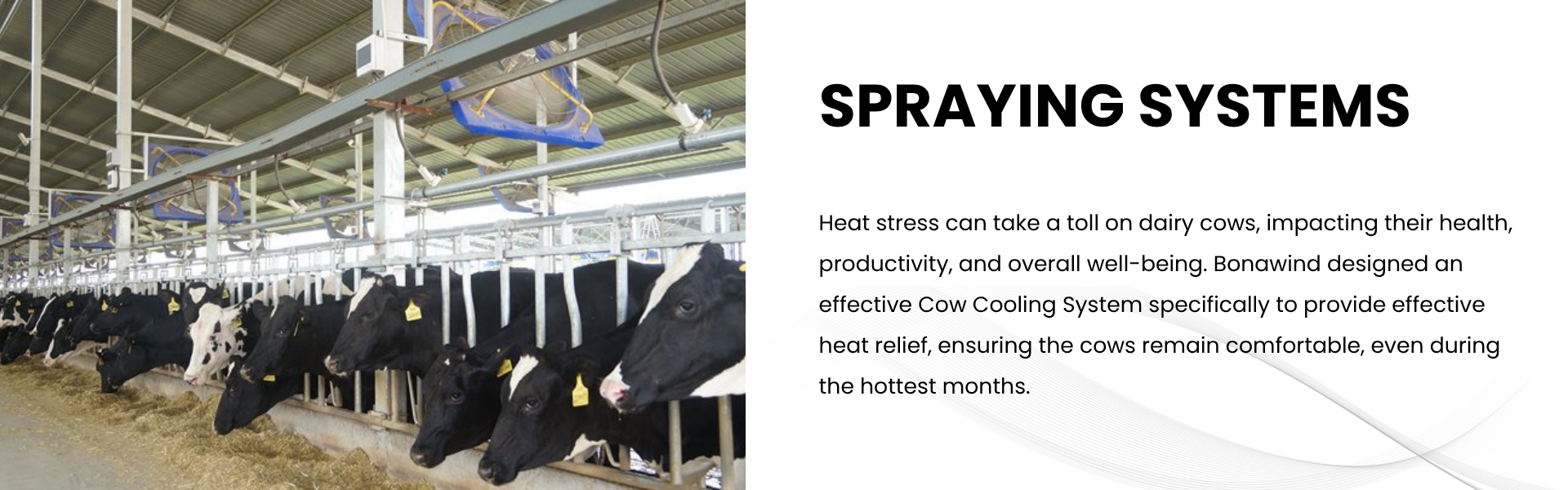

EFFECTIVE SPRAYING SYSTEMS FOR DAIRY COW COOLING

Our spraying system for dairy farms is engineered to reduce heat stress and enhance cow comfort. It includes two targeted cow cooling solutions: the soaking system and the misting system. Each system is designed to meet specific needs based on barn layout, herd density, and local climate conditions, ensuring efficient and reliable heat stress management for dairy cows.

High-Pressure Misting

Recommended use

- In a Cross-ventilated or Tunnel-ventilated barn, the High-Pressure Misting system should be installed at and near the inlet to maximize cooling efficiency.

- In a naturally-ventilated barn, the High-Pressure Misting system should be installed over or on fans to ensure equal distribution of the misting.

- Work best with Bonawind Circulation Fans

Bonawind Soaking Systems

A vital tool in the battle of heat stress, Bonawind soaking system lines are designed to provide additional cooling in barns and parlors. Our soaking system uses low pressure and expels large water droplets, which allow water to penetrate a cow’s hair and drench her back. Soaking systems are a key component to prioritizing cow comfort.

Feedlane Soaking Features

- Components are designed and manufactured for quick & easy installation.

- Standard nozzle spacing of 1.52m (5’)

- A ball valve, water filter and solenoid valve at the inlet ensures trouble-free operations.

- Galvanized pipes and Stainless-steel nozzles.

- No welding required with our mounting brackets, clamps and pipe connectors.

BENEFITS OF USING A SPRAYING SYSTEM FOR DAIRY COW COOLING

Implementing a spraying system is an effective way to manage heat stress in dairy farms and improve cow comfort. By combining soaking systems and fogging systems, farmers can create a cooler environment for their herds, leading to better health and productivity. Here are the key benefits:

Spraying systems help lower the body temperature of dairy cows during hot weather, reducing the risk of heat stress and related health problems.

- A properly installed cow cooling system ensures a more comfortable environment, which leads to calmer and healthier cows.

- Comfortable cows eat better and produce more milk. Cooling systems help maintain steady feed intake and optimize milk yield, especially during summer months.

- Lower heat stress supports reproductive performance and helps prevent common heat-related conditions like mastitis and reduced fertility.

Spraying systems can be applied in holding pens, feed alleys, milking parlors, and barns, making them versatile solutions for different dairy farm layouts.

- Both soaking and fogging systems are designed for efficient operation, providing effective cooling with minimal water and power consumption.

- Farmers can choose soaking, fogging, or a combination system depending on humidity levels, ventilation conditions, and regional climate, making spraying systems highly adaptable.

- Spraying systems can be easily combined with ventilation fans and other cooling methods to create a comprehensive heat stress management strategy.

Contact Us

Goodwind LLC

- Address: 14615 Blue Ash Dr. Houston, TX 77090

- Telephone: 877 814 6639

- WhatsApp: 713 257 4877

- Email: info@bonawind.com