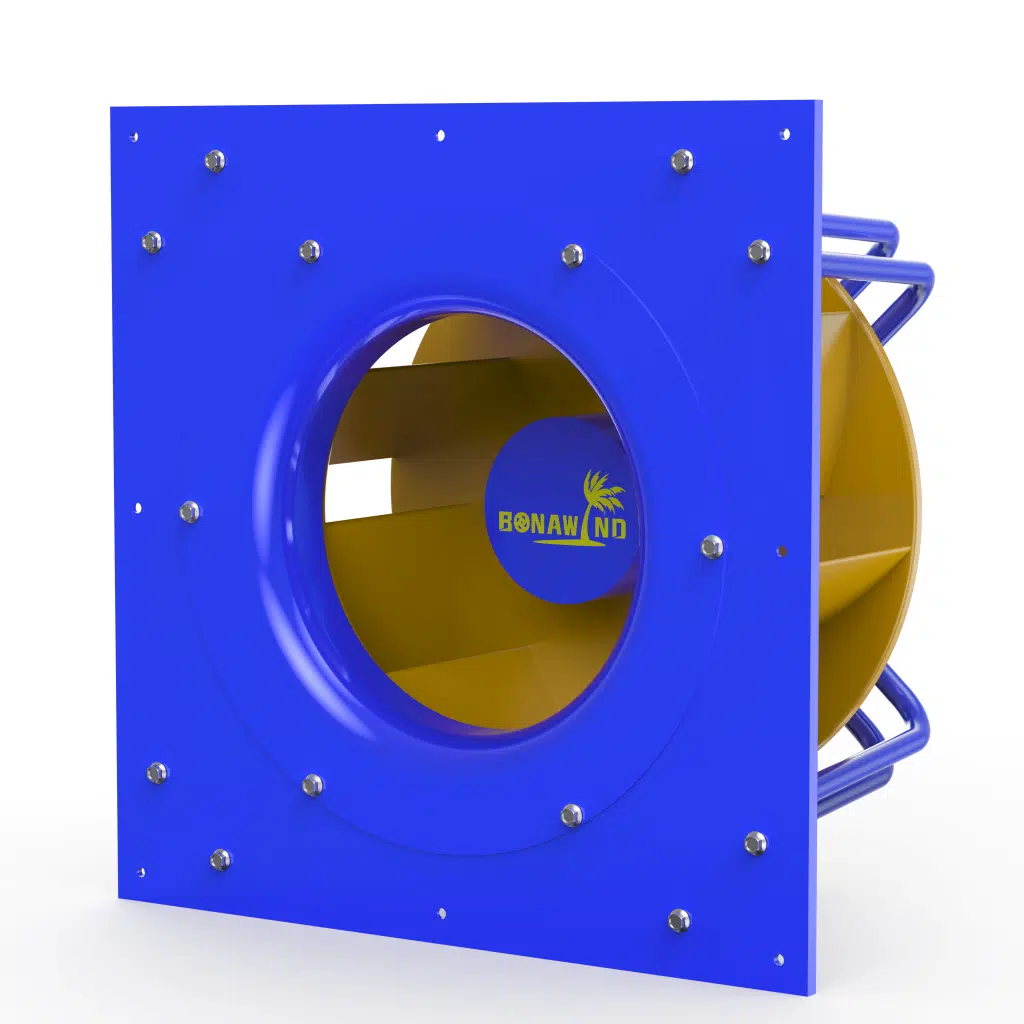

What Is a Centrifugal Fan? Structure and Working Principle

A centrifugal fan is a type of ventilation equipment widely used in industrial, commercial, and residential applications. It operates by generating centrifugal force through the rotation of an impeller, which draws air in and accelerates it outward, enabling the movement and delivery of air or other gases. Centrifugal fans play an important role in ventilation systems, HVAC systems, industrial exhaust treatment, and material conveying.

1. Definition of a Centrifugal Fan

A centrifugal fan is a fan that operates based on the principle of centrifugal force. Its core component is the impeller. When the impeller rotates at high speed, air is drawn into the center and thrown outward by centrifugal force, achieving air delivery. Compared with axial fans, centrifugal fans provide higher pressure but relatively lower airflow volume, making them suitable for applications requiring high static pressure or resistance.

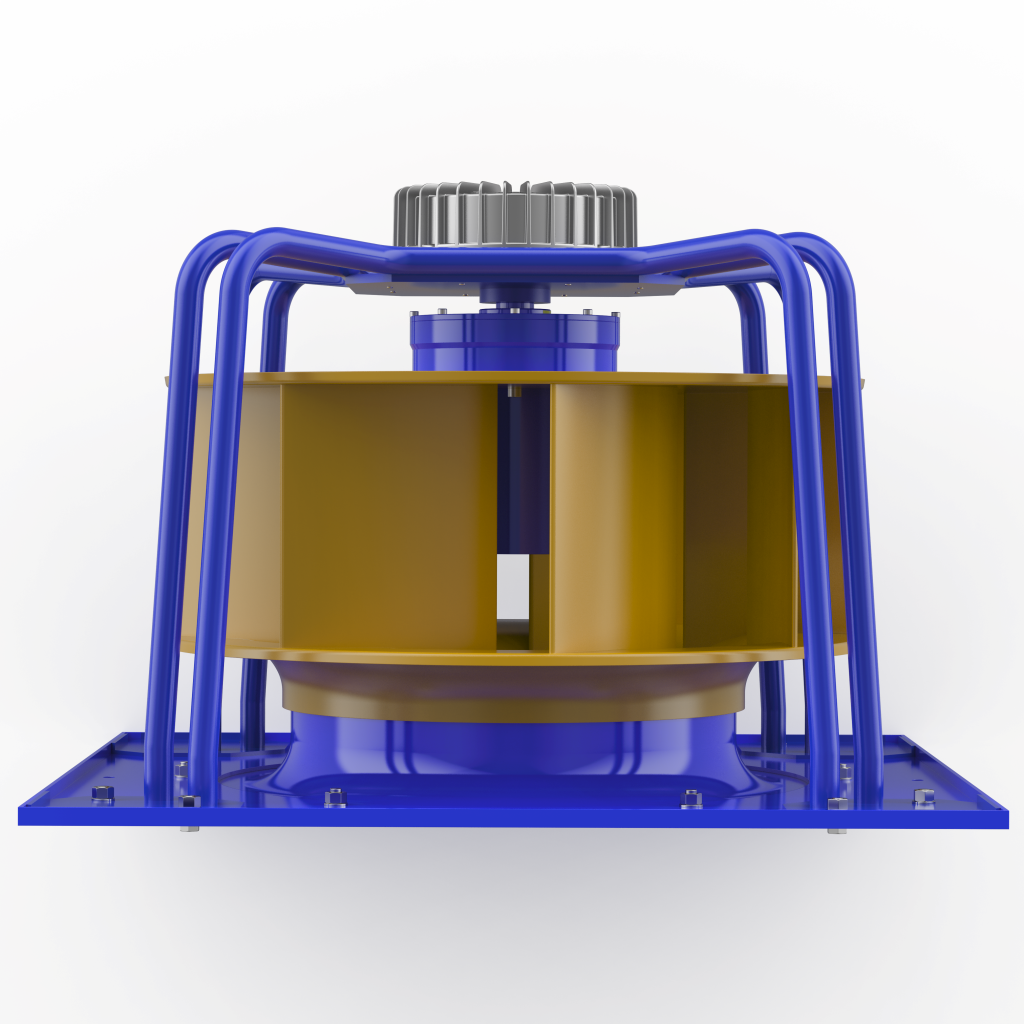

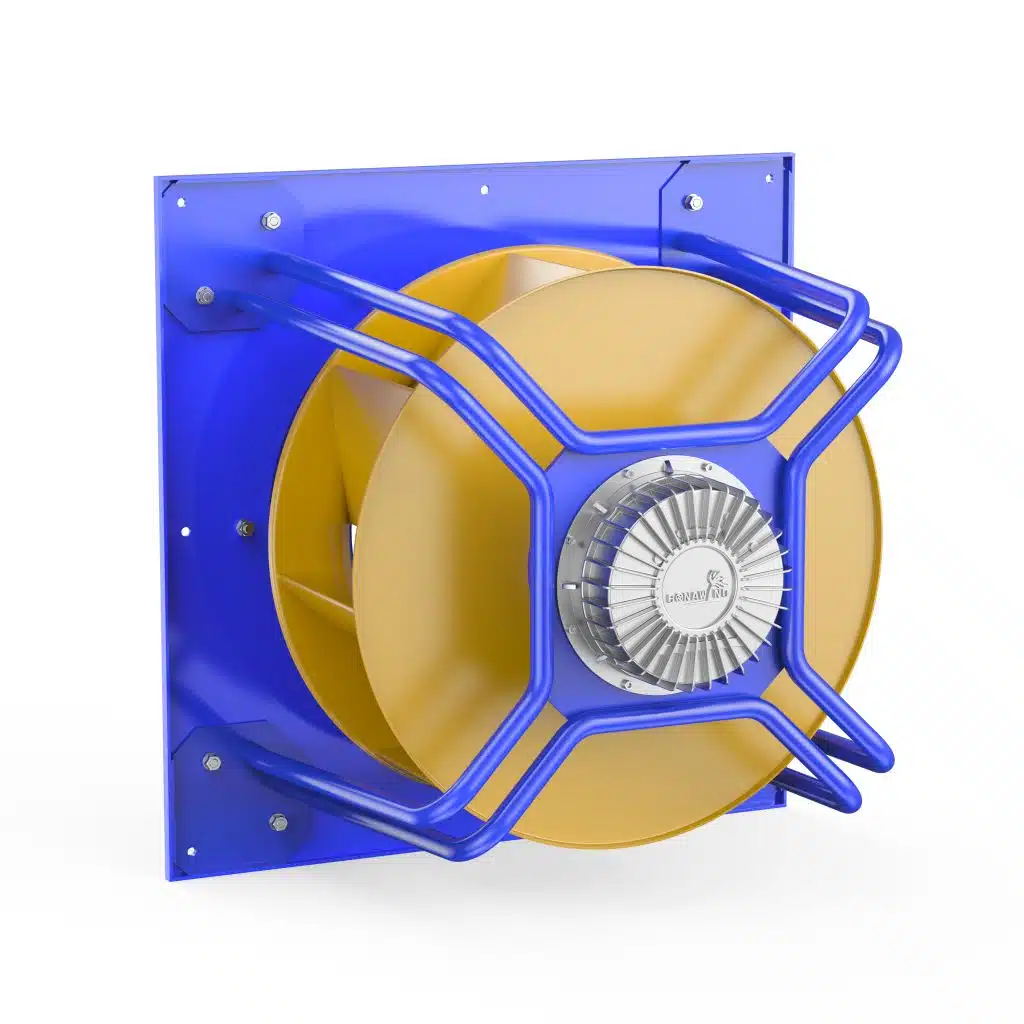

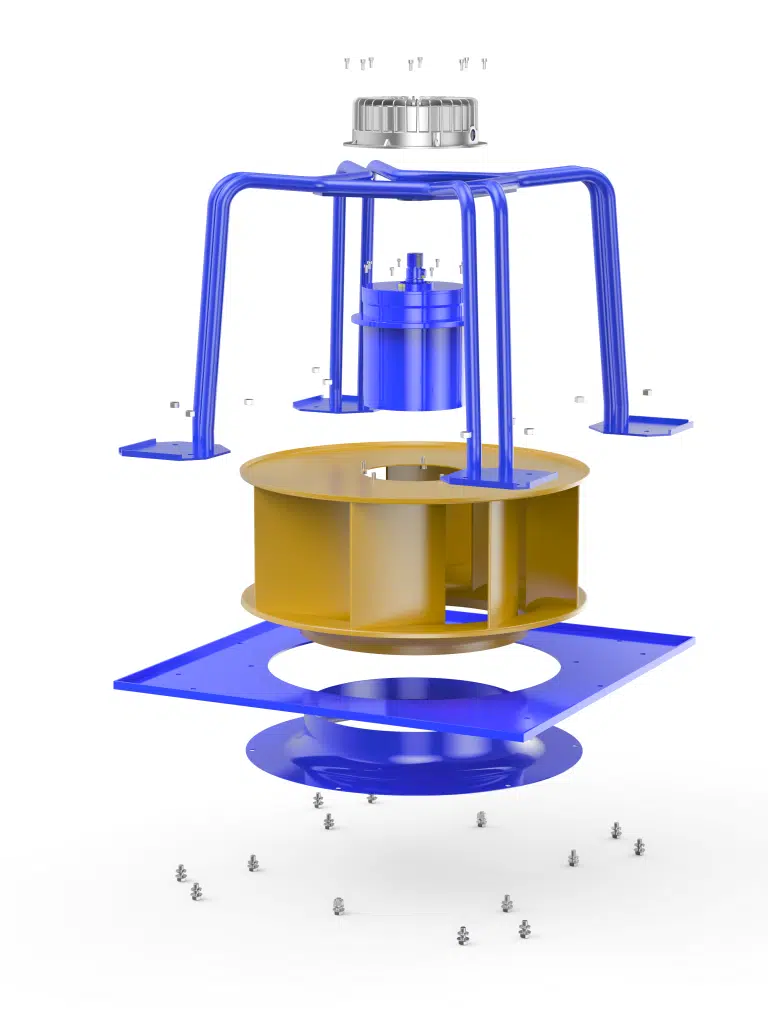

2. Main Components of a Centrifugal Fan

Impeller

The impeller is the key component of a centrifugal fan, consisting of a hub and multiple blades. The blade shape and angle are precisely designed to ensure efficient air intake and acceleration. The rotation direction and blade angle directly affect fan performance. Common materials include aluminum alloy, stainless steel, and cast iron, depending on the application and gas characteristics.Volute (Casing)

The volute, often shaped like a snail shell, collects and directs the air discharged from the impeller to the outlet. Its structural design significantly impacts fan efficiency. It must withstand pressure while minimizing turbulence and energy loss through optimized flow passages.

Inlet

The inlet is where air enters the fan. Its geometry and position influence airflow distribution and efficiency. It is typically round or rectangular and located at the center of the impeller. A well-designed inlet ensures uniform airflow and reduces energy loss.Motor

The motor provides the rotational power for the impeller. Centrifugal fans typically use three-phase permanent magnet motors, with power and speed selected based on design requirements.Frame and Base

The frame and base support the entire fan assembly and maintain stability during operation. They are usually made of steel with sufficient strength and rigidity. Larger fans may include vibration-damping mounts to reduce noise and vibration transfer.

3. Working Principle of a Centrifugal Fan

Air Intake

As the impeller rotates, air near the center is thrown outward, creating a low-pressure zone. External air is then drawn into the inlet under atmospheric pressure.Air Acceleration

Once inside the impeller, the air is accelerated along the curved blades. As its velocity increases, centrifugal force drives the air toward the outer edge of the impeller.Air Discharge

The high-velocity air exits the impeller and enters the volute, where the flow gradually slows down and kinetic energy is converted into static pressure before being discharged through the outlet.Energy Conversion

The fan converts mechanical energy from the motor into airflow energy. During this process, the rotational kinetic energy of the air is transformed into pressure energy, enabling efficient air handling.

Summary

A centrifugal fan is a precision-engineered ventilation device that transports air using centrifugal force. With advantages such as high pressure output, stable airflow, adjustable performance, and high efficiency, it is widely used in industrial production, building ventilation, environmental engineering, and material conveying systems.

Contact Us

Goodwind LLC

- Address: 14615 Blue Ash Dr. Houston, TX 77090

- Address: 6661 Canyon Dr Suite E, Amarillo, TX 79110

- Telephone: 469 924 2829

- Email: info@bonawind.com